Catch Daily Deals!

Go to Daily Deals Section-

Weight Filling Machines

20-5000G SEMI WEIGHING FILLING MACHINE

Working voltage: 220V / 110V / 50HZ / 60HZ

Rated power: 350W

Packing speed: 6-15 bags / packing Weighing range: 20-5000G

Incorrect value: 2G (depending on the product to be filled)

This product is suitable for granular, powdered products, rice, millet, cereals, vegetable seeds, fertilizers, tea, wolfberry, dog food, fish food, dried fruits, nuts, medicinal salts, seasonings, red dates, walnuts, Chestnuts, dried longan, electronic originals, hardware originals, plastic parts, etc

SKU: n/a -

Weight Filling Machines

99.9 SEMI WEIGHING FILLING MACHINE

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 1 to 99.9 grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

The complete structure is made up of stainless steel with an open type bin. The structure is simple and easy to clean.

Digital numbers for denoting

- weight of the powder for a single output.

- The total standard expected weight per output.

- Number of times output received through the hopper

Requires electricity for its functioning. The supply requirement is a 220 volt 50 Hz AC power supply.

Please note that the weight of this full machine is 10 kg.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

SKU: n/a -

Weight Filling Machines

999 SEMI WEIGHING FILLING MACHINE

DESCRIPTION

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 100 to 999grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

Complete structure is made up of stainless steel with open type bin. Structure is simple and easy to clean.

Digital numbers for denoting

- weight of the powder for a single output.

- Total standard expected weight per output.

- Number of times output received through the hopper

Requires electricity for its functioning. Supply requirement is 220 volt 50 Hz AC power supply.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

SKU: n/a -

Semi-Auto Stretch Film Wrapping Machine

Semi-Auto Stretch Film Wrapping Machine

Product Description

As one of India’s leading manufacturers and suppliers, we are offering an exclusive range of Box Stretch Wrapping Machine. These machines are used for stretch film wrapping around the packaging boxes in different industries like cosmetic, textiles, electrical, automotive, food & beverage and fertilizer. We employ ultra modern techniques and quality approved materials to design these machines in accordance with industry set norms and standards. Our product is best known for its robust construction, corrosion resistant body and easy operation.Box Stretch Wrapping Machine Features:

1) Digital display to show stretch percentage and film consumption.

2) Continues motion mechanism that required very less maintenance.

3) Stringent quality checking done before final shipment.SKU: n/a -

Liquid Filling Machines

Double Head Paste Filling Machine

Filling Range

Machine Other Details

- This machine is the semi-automatic piston type pasty liquid filling

- This machine is reasonable in design, small and exquisite in model, saving the place.

- The part contacting materials is made of 316L & Hopper 304L stainless steel

- Both filling volume and filling speed can be adjusted, with high filling accuracy.

- Filling head adopts anti-leakage and lifting device.

- Hopper Capacity 40-50Kg.

Model Preferred Filling Range(ml)

- 100(ml) 5-100

- 500(ml) 20-500

- 1000(ml) 100-1000

- 2600(ml) 1000-2600

SKU: n/a -

Liquid Filling Machines

Single Head Paste Filling Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L & Hopper 304L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

Hopper Capacity 40-50Kg.SKU: n/a -

Liquid Filling Machines

Double Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.SKU: n/a -

Liquid Filling Machines

Liquid Single Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.SKU: n/a -

Sealer

FS-300 Plastic Sealing Machine

The Series plastic film sealer is the perfect sealer for PE and PP bags(including cellophane, bubble wraps, shrink wraps and thick heavy duty bags and so on), to package various kinds of candy, foodstuff, general merchandises, stationery, medicine, local specially, electric elements ect

SKU: n/a

-

L Sealer Machines

L-Bar Sealer

Sealing Cutting Machine can convey the products automatically into shrink tunnelthrough conveying belt for shrink packaging after sealing & cutting. Equipped with shrinktunnel to reach higher working capacity.

Sealing Cutting Machine is suitable for shrink packing electronic products, hardware,software, foodstuff, printing, pharmacy, floor, ceramics etc in small amount.Additional Information:

- Packaging Details: Wood

SKU: n/a -

Batch Coding

MY-380F Solid Ink Coding Machine

Backed by our efficient workforce, we are able to design and develop a wide range of Dry Ink Coding Machines. These are widely demanded by several industries like food, pharmaceutical and chemical. In addition to this, we have a team of expert quality controllers, which checks all the products on various parameters to ensure zero defect. We also provide tailor-made solution for all the products as per the specifications laid down by the customers.

Ideal for printing statutory markings/ coding on plastic / paper pouches, duplex boards / duplex cartons, labels etc.

Features:- Higher production speeds

- Batch feeding of print media

- Zero spillage of ink

- Lower coding costs

- Print counter

- Photo electric sensor for adjustment of print position

Additional Information:

- Delivery Time: 2 Days

SKU: n/a -

Can Sealer Sealing Machines

Manual Can Seamer

Can Seamer Intelligent can sealing machine Smart panel Beverage sealing machine milk tea coffee bubble drink bottle sealing

Product Name: Smart Can Sealing Machine

Type: Filling and Sealing Machine

Size: 550*350*202mm

Production capacity: 20 times / minute

Sealing width: 52mm

Sealing speed: 5 seconds

power:415w

Packaging material: plastic

Degree of automation: manual

Film thickness: 3mm

Weight: 35kg

Suitable for: Western food shop equipment, cake room equipment, Chinese food shop equipment, beverage shop equipment, coffee shop equipment, tea restaurant equipmentSKU: n/a -

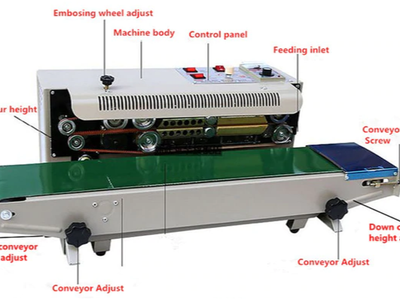

Continuous Band Sealers

Packing Machine

Automatic Continuous Band Sealer and step less speed adjusting transmission mechanism. It can seal plastic films of various materials it is also suitable for small bags packaging .

Suitable for BOPP, Multi Layer, Laminated, Polysterpoly, Alu. Foil

All type of sealable materials in every thickness can be sealed .

Sealing length is unlimited.

Reliable Sealing quality.

Compact design.

Easy To Use.

Fast Work.Additional Information:

- Production Capacity: 50

- Delivery Time: 1 DAYS

- Packaging Details: CARTON

SKU: n/a -

Continuous Band Sealers

Continuous Band Sealer

Automatic Continuous Band Sealer and step less speed adjusting transmission mechanism. It can seal plastic films of various materials it is also suitable for small bags packaging .

Additional Information:

- Delivery Time: IMMEDIATE

- Packaging Details: CARTON PACKAGING

SKU: n/a -

Carton Strapping Machines

Automatic Strapping Machine

Features:Strap at quick speed and with high efficiency. Only takes 2 seconds for strapping one polypropylene strap.Instant heating systems, low voltage, light, safety,Automatic stopping devices save electricity and make it practical.Electromagnetic clutch, quick and smooth. Coupled-axle transmission, quick speed, low noise, low wear and tear, and low breakdown rate.Strap width from 8-19mm adjustable.

SKU: n/a -

Carton Strapping Machines

Automatic Strapping Machine

Rapid speed: 2.0sec/per cycle, 30cycles/per min

Easy Maintenance: No Greasing, Mechanism is stable and durable, Easy operation

Tension Adjustment: Can be adjustable at well, Max. Tension is over 90kgs

Precision Structure: Main machine’s component is made of aluminum alloy. Control System is compatible

Add on a safety device, built for 24 hrs continuous operation

Easy loading or unloading: To load or unload the strapping roll is convenient due to the dispenser is placed outside

Extensive applications: Can be independent operation or combine with other machines for unmanned

Electric appliance adopted: “MITSUBISHI” PLC control, and “ORMON” photoelectric switch control

Additional Information:

- Production Capacity: Built for 24 hrs continuous operation

SKU: n/a -

Carton Strapping Machines

Semi-Automatic Strapping Machine

- Strapping Machine tension -40-400N adjustable

- Strapping Machine speed -0.53 sec./strap

- Strap width -6-15mm

- Power supply -220V/1P

- Power consumption -0.2KVA

- Strapping Machine size-809*520*760MM

- Strapping Machine weight -67KG

♦ Standard accessory, it’s advantage is stable quality, durable material,and easy maintenance.

♦ Special design-control PP strap cooling time. It can make the PP strap to fasten well in any time.

♦ “Electricity-Saving” device, the motor automatically stops running at once after one circle strap to reduce the normal wear and to prolong the Strapping Machine life.

♦ Non-Fast heater plate, it will increase the work efficiency. The advanced P.C.B microchip circuit board control system,less malfunction and easy maintenance.

♦ Installing an auxiliary feed/reset switch and tension adjust switch at the control panel makes you operate more conveniently.Additional Information:

- Packaging Details: wooden b

SKU: n/a -

Carton Strapping Machines

Strapping Machine

Product Description

- Strapping Machine tension -40-400N adjustable

- Strapping Machine speed -0.53 sec./strap

- Strap width -6-15mm

- Power supply -220V/1P

- Power consumption -0.2KVA

- Strapping Machine size-809*520*760MM

- Strapping Machine weight -67KG

♦ Standard accessory, it’s advantage is stable quality, durable material,and easy maintenance.

♦ Special design-control PP strap cooling time. It can make the PP strap to fasten well in any time.

♦ “Electricity-Saving” device, the motor automatically stops running at once after one circle strap to reduce the normal wear and to prolong the Strapping Machine life.

♦ Non-Fast heater plate, it will increase the work efficiency. The advanced P.C.B microchip circuit board control system,less malfunction and easy maintenance.

♦ Installing an auxiliary feed/reset switch and tension adjust switch at the control panel makes you operate more conveniently.SKU: n/a

-

Weight Filling Machines

20-5000G SEMI WEIGHING FILLING MACHINE

Working voltage: 220V / 110V / 50HZ / 60HZ

Rated power: 350W

Packing speed: 6-15 bags / packing Weighing range: 20-5000G

Incorrect value: 2G (depending on the product to be filled)

This product is suitable for granular, powdered products, rice, millet, cereals, vegetable seeds, fertilizers, tea, wolfberry, dog food, fish food, dried fruits, nuts, medicinal salts, seasonings, red dates, walnuts, Chestnuts, dried longan, electronic originals, hardware originals, plastic parts, etc

SKU: n/a -

Weight Filling Machines

99.9 SEMI WEIGHING FILLING MACHINE

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 1 to 99.9 grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

The complete structure is made up of stainless steel with an open type bin. The structure is simple and easy to clean.

Digital numbers for denoting

- weight of the powder for a single output.

- The total standard expected weight per output.

- Number of times output received through the hopper

Requires electricity for its functioning. The supply requirement is a 220 volt 50 Hz AC power supply.

Please note that the weight of this full machine is 10 kg.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

SKU: n/a -

Weight Filling Machines

999 SEMI WEIGHING FILLING MACHINE

DESCRIPTION

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 100 to 999grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

Complete structure is made up of stainless steel with open type bin. Structure is simple and easy to clean.

Digital numbers for denoting

- weight of the powder for a single output.

- Total standard expected weight per output.

- Number of times output received through the hopper

Requires electricity for its functioning. Supply requirement is 220 volt 50 Hz AC power supply.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

SKU: n/a -

Semi-Auto Stretch Film Wrapping Machine

Semi-Auto Stretch Film Wrapping Machine

Product Description

As one of India’s leading manufacturers and suppliers, we are offering an exclusive range of Box Stretch Wrapping Machine. These machines are used for stretch film wrapping around the packaging boxes in different industries like cosmetic, textiles, electrical, automotive, food & beverage and fertilizer. We employ ultra modern techniques and quality approved materials to design these machines in accordance with industry set norms and standards. Our product is best known for its robust construction, corrosion resistant body and easy operation.Box Stretch Wrapping Machine Features:

1) Digital display to show stretch percentage and film consumption.

2) Continues motion mechanism that required very less maintenance.

3) Stringent quality checking done before final shipment.SKU: n/a -

Liquid Filling Machines

Double Head Paste Filling Machine

Filling Range

Machine Other Details

- This machine is the semi-automatic piston type pasty liquid filling

- This machine is reasonable in design, small and exquisite in model, saving the place.

- The part contacting materials is made of 316L & Hopper 304L stainless steel

- Both filling volume and filling speed can be adjusted, with high filling accuracy.

- Filling head adopts anti-leakage and lifting device.

- Hopper Capacity 40-50Kg.

Model Preferred Filling Range(ml)

- 100(ml) 5-100

- 500(ml) 20-500

- 1000(ml) 100-1000

- 2600(ml) 1000-2600

SKU: n/a -

Liquid Filling Machines

Single Head Paste Filling Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L & Hopper 304L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

Hopper Capacity 40-50Kg.SKU: n/a -

Liquid Filling Machines

Double Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.SKU: n/a -

Liquid Filling Machines

Liquid Single Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.SKU: n/a -

Sealer

FS-300 Plastic Sealing Machine

The Series plastic film sealer is the perfect sealer for PE and PP bags(including cellophane, bubble wraps, shrink wraps and thick heavy duty bags and so on), to package various kinds of candy, foodstuff, general merchandises, stationery, medicine, local specially, electric elements ect

SKU: n/a

-

L Sealer Machines

L-Bar Sealer

Sealing Cutting Machine can convey the products automatically into shrink tunnelthrough conveying belt for shrink packaging after sealing & cutting. Equipped with shrinktunnel to reach higher working capacity.

Sealing Cutting Machine is suitable for shrink packing electronic products, hardware,software, foodstuff, printing, pharmacy, floor, ceramics etc in small amount.Additional Information:

- Packaging Details: Wood

SKU: n/a -

Batch Coding

MY-380F Solid Ink Coding Machine

Backed by our efficient workforce, we are able to design and develop a wide range of Dry Ink Coding Machines. These are widely demanded by several industries like food, pharmaceutical and chemical. In addition to this, we have a team of expert quality controllers, which checks all the products on various parameters to ensure zero defect. We also provide tailor-made solution for all the products as per the specifications laid down by the customers.

Ideal for printing statutory markings/ coding on plastic / paper pouches, duplex boards / duplex cartons, labels etc.

Features:- Higher production speeds

- Batch feeding of print media

- Zero spillage of ink

- Lower coding costs

- Print counter

- Photo electric sensor for adjustment of print position

Additional Information:

- Delivery Time: 2 Days

SKU: n/a -

Can Sealer Sealing Machines

Manual Can Seamer

Can Seamer Intelligent can sealing machine Smart panel Beverage sealing machine milk tea coffee bubble drink bottle sealing

Product Name: Smart Can Sealing Machine

Type: Filling and Sealing Machine

Size: 550*350*202mm

Production capacity: 20 times / minute

Sealing width: 52mm

Sealing speed: 5 seconds

power:415w

Packaging material: plastic

Degree of automation: manual

Film thickness: 3mm

Weight: 35kg

Suitable for: Western food shop equipment, cake room equipment, Chinese food shop equipment, beverage shop equipment, coffee shop equipment, tea restaurant equipmentSKU: n/a -

Continuous Band Sealers

Packing Machine

Automatic Continuous Band Sealer and step less speed adjusting transmission mechanism. It can seal plastic films of various materials it is also suitable for small bags packaging .

Suitable for BOPP, Multi Layer, Laminated, Polysterpoly, Alu. Foil

All type of sealable materials in every thickness can be sealed .

Sealing length is unlimited.

Reliable Sealing quality.

Compact design.

Easy To Use.

Fast Work.Additional Information:

- Production Capacity: 50

- Delivery Time: 1 DAYS

- Packaging Details: CARTON

SKU: n/a -

Continuous Band Sealers

Continuous Band Sealer

Automatic Continuous Band Sealer and step less speed adjusting transmission mechanism. It can seal plastic films of various materials it is also suitable for small bags packaging .

Additional Information:

- Delivery Time: IMMEDIATE

- Packaging Details: CARTON PACKAGING

SKU: n/a -

Carton Strapping Machines

Automatic Strapping Machine

Features:Strap at quick speed and with high efficiency. Only takes 2 seconds for strapping one polypropylene strap.Instant heating systems, low voltage, light, safety,Automatic stopping devices save electricity and make it practical.Electromagnetic clutch, quick and smooth. Coupled-axle transmission, quick speed, low noise, low wear and tear, and low breakdown rate.Strap width from 8-19mm adjustable.

SKU: n/a -

Carton Strapping Machines

Automatic Strapping Machine

Rapid speed: 2.0sec/per cycle, 30cycles/per min

Easy Maintenance: No Greasing, Mechanism is stable and durable, Easy operation

Tension Adjustment: Can be adjustable at well, Max. Tension is over 90kgs

Precision Structure: Main machine’s component is made of aluminum alloy. Control System is compatible

Add on a safety device, built for 24 hrs continuous operation

Easy loading or unloading: To load or unload the strapping roll is convenient due to the dispenser is placed outside

Extensive applications: Can be independent operation or combine with other machines for unmanned

Electric appliance adopted: “MITSUBISHI” PLC control, and “ORMON” photoelectric switch control

Additional Information:

- Production Capacity: Built for 24 hrs continuous operation

SKU: n/a -

Carton Strapping Machines

Semi-Automatic Strapping Machine

- Strapping Machine tension -40-400N adjustable

- Strapping Machine speed -0.53 sec./strap

- Strap width -6-15mm

- Power supply -220V/1P

- Power consumption -0.2KVA

- Strapping Machine size-809*520*760MM

- Strapping Machine weight -67KG

♦ Standard accessory, it’s advantage is stable quality, durable material,and easy maintenance.

♦ Special design-control PP strap cooling time. It can make the PP strap to fasten well in any time.

♦ “Electricity-Saving” device, the motor automatically stops running at once after one circle strap to reduce the normal wear and to prolong the Strapping Machine life.

♦ Non-Fast heater plate, it will increase the work efficiency. The advanced P.C.B microchip circuit board control system,less malfunction and easy maintenance.

♦ Installing an auxiliary feed/reset switch and tension adjust switch at the control panel makes you operate more conveniently.Additional Information:

- Packaging Details: wooden b

SKU: n/a -

Carton Strapping Machines

Strapping Machine

Product Description

- Strapping Machine tension -40-400N adjustable

- Strapping Machine speed -0.53 sec./strap

- Strap width -6-15mm

- Power supply -220V/1P

- Power consumption -0.2KVA

- Strapping Machine size-809*520*760MM

- Strapping Machine weight -67KG

♦ Standard accessory, it’s advantage is stable quality, durable material,and easy maintenance.

♦ Special design-control PP strap cooling time. It can make the PP strap to fasten well in any time.

♦ “Electricity-Saving” device, the motor automatically stops running at once after one circle strap to reduce the normal wear and to prolong the Strapping Machine life.

♦ Non-Fast heater plate, it will increase the work efficiency. The advanced P.C.B microchip circuit board control system,less malfunction and easy maintenance.

♦ Installing an auxiliary feed/reset switch and tension adjust switch at the control panel makes you operate more conveniently.SKU: n/a

-

Weight Filling Machines

20-5000G SEMI WEIGHING FILLING MACHINE

Working voltage: 220V / 110V / 50HZ / 60HZ

Rated power: 350W

Packing speed: 6-15 bags / packing Weighing range: 20-5000G

Incorrect value: 2G (depending on the product to be filled)

This product is suitable for granular, powdered products, rice, millet, cereals, vegetable seeds, fertilizers, tea, wolfberry, dog food, fish food, dried fruits, nuts, medicinal salts, seasonings, red dates, walnuts, Chestnuts, dried longan, electronic originals, hardware originals, plastic parts, etc

SKU: n/a -

Weight Filling Machines

99.9 SEMI WEIGHING FILLING MACHINE

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 1 to 99.9 grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

The complete structure is made up of stainless steel with an open type bin. The structure is simple and easy to clean.

Digital numbers for denoting

- weight of the powder for a single output.

- The total standard expected weight per output.

- Number of times output received through the hopper

Requires electricity for its functioning. The supply requirement is a 220 volt 50 Hz AC power supply.

Please note that the weight of this full machine is 10 kg.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

SKU: n/a -

Weight Filling Machines

999 SEMI WEIGHING FILLING MACHINE

DESCRIPTION

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 100 to 999grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

Complete structure is made up of stainless steel with open type bin. Structure is simple and easy to clean.

Digital numbers for denoting

- weight of the powder for a single output.

- Total standard expected weight per output.

- Number of times output received through the hopper

Requires electricity for its functioning. Supply requirement is 220 volt 50 Hz AC power supply.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

SKU: n/a -

Semi-Auto Stretch Film Wrapping Machine

Semi-Auto Stretch Film Wrapping Machine

Product Description

As one of India’s leading manufacturers and suppliers, we are offering an exclusive range of Box Stretch Wrapping Machine. These machines are used for stretch film wrapping around the packaging boxes in different industries like cosmetic, textiles, electrical, automotive, food & beverage and fertilizer. We employ ultra modern techniques and quality approved materials to design these machines in accordance with industry set norms and standards. Our product is best known for its robust construction, corrosion resistant body and easy operation.Box Stretch Wrapping Machine Features:

1) Digital display to show stretch percentage and film consumption.

2) Continues motion mechanism that required very less maintenance.

3) Stringent quality checking done before final shipment.SKU: n/a -

Liquid Filling Machines

Double Head Paste Filling Machine

Filling Range

Machine Other Details

- This machine is the semi-automatic piston type pasty liquid filling

- This machine is reasonable in design, small and exquisite in model, saving the place.

- The part contacting materials is made of 316L & Hopper 304L stainless steel

- Both filling volume and filling speed can be adjusted, with high filling accuracy.

- Filling head adopts anti-leakage and lifting device.

- Hopper Capacity 40-50Kg.

Model Preferred Filling Range(ml)

- 100(ml) 5-100

- 500(ml) 20-500

- 1000(ml) 100-1000

- 2600(ml) 1000-2600

SKU: n/a -

Liquid Filling Machines

Single Head Paste Filling Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L & Hopper 304L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

Hopper Capacity 40-50Kg.SKU: n/a -

Liquid Filling Machines

Double Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.SKU: n/a -

Liquid Filling Machines

Liquid Single Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.SKU: n/a -

Sealer

FS-300 Plastic Sealing Machine

The Series plastic film sealer is the perfect sealer for PE and PP bags(including cellophane, bubble wraps, shrink wraps and thick heavy duty bags and so on), to package various kinds of candy, foodstuff, general merchandises, stationery, medicine, local specially, electric elements ect

SKU: n/a

-

L Sealer Machines

L-Bar Sealer

Sealing Cutting Machine can convey the products automatically into shrink tunnelthrough conveying belt for shrink packaging after sealing & cutting. Equipped with shrinktunnel to reach higher working capacity.

Sealing Cutting Machine is suitable for shrink packing electronic products, hardware,software, foodstuff, printing, pharmacy, floor, ceramics etc in small amount.Additional Information:

- Packaging Details: Wood

SKU: n/a -

Batch Coding

MY-380F Solid Ink Coding Machine

Backed by our efficient workforce, we are able to design and develop a wide range of Dry Ink Coding Machines. These are widely demanded by several industries like food, pharmaceutical and chemical. In addition to this, we have a team of expert quality controllers, which checks all the products on various parameters to ensure zero defect. We also provide tailor-made solution for all the products as per the specifications laid down by the customers.

Ideal for printing statutory markings/ coding on plastic / paper pouches, duplex boards / duplex cartons, labels etc.

Features:- Higher production speeds

- Batch feeding of print media

- Zero spillage of ink

- Lower coding costs

- Print counter

- Photo electric sensor for adjustment of print position

Additional Information:

- Delivery Time: 2 Days

SKU: n/a -

Can Sealer Sealing Machines

Manual Can Seamer

Can Seamer Intelligent can sealing machine Smart panel Beverage sealing machine milk tea coffee bubble drink bottle sealing

Product Name: Smart Can Sealing Machine

Type: Filling and Sealing Machine

Size: 550*350*202mm

Production capacity: 20 times / minute

Sealing width: 52mm

Sealing speed: 5 seconds

power:415w

Packaging material: plastic

Degree of automation: manual

Film thickness: 3mm

Weight: 35kg

Suitable for: Western food shop equipment, cake room equipment, Chinese food shop equipment, beverage shop equipment, coffee shop equipment, tea restaurant equipmentSKU: n/a -

Continuous Band Sealers

Packing Machine

Automatic Continuous Band Sealer and step less speed adjusting transmission mechanism. It can seal plastic films of various materials it is also suitable for small bags packaging .

Suitable for BOPP, Multi Layer, Laminated, Polysterpoly, Alu. Foil

All type of sealable materials in every thickness can be sealed .

Sealing length is unlimited.

Reliable Sealing quality.

Compact design.

Easy To Use.

Fast Work.Additional Information:

- Production Capacity: 50

- Delivery Time: 1 DAYS

- Packaging Details: CARTON

SKU: n/a -

Continuous Band Sealers

Continuous Band Sealer

Automatic Continuous Band Sealer and step less speed adjusting transmission mechanism. It can seal plastic films of various materials it is also suitable for small bags packaging .

Additional Information:

- Delivery Time: IMMEDIATE

- Packaging Details: CARTON PACKAGING

SKU: n/a -

Carton Strapping Machines

Automatic Strapping Machine

Features:Strap at quick speed and with high efficiency. Only takes 2 seconds for strapping one polypropylene strap.Instant heating systems, low voltage, light, safety,Automatic stopping devices save electricity and make it practical.Electromagnetic clutch, quick and smooth. Coupled-axle transmission, quick speed, low noise, low wear and tear, and low breakdown rate.Strap width from 8-19mm adjustable.

SKU: n/a -

Carton Strapping Machines

Automatic Strapping Machine

Rapid speed: 2.0sec/per cycle, 30cycles/per min

Easy Maintenance: No Greasing, Mechanism is stable and durable, Easy operation

Tension Adjustment: Can be adjustable at well, Max. Tension is over 90kgs

Precision Structure: Main machine’s component is made of aluminum alloy. Control System is compatible

Add on a safety device, built for 24 hrs continuous operation

Easy loading or unloading: To load or unload the strapping roll is convenient due to the dispenser is placed outside

Extensive applications: Can be independent operation or combine with other machines for unmanned

Electric appliance adopted: “MITSUBISHI” PLC control, and “ORMON” photoelectric switch control

Additional Information:

- Production Capacity: Built for 24 hrs continuous operation

SKU: n/a -

Carton Strapping Machines

Semi-Automatic Strapping Machine

- Strapping Machine tension -40-400N adjustable

- Strapping Machine speed -0.53 sec./strap

- Strap width -6-15mm

- Power supply -220V/1P

- Power consumption -0.2KVA

- Strapping Machine size-809*520*760MM

- Strapping Machine weight -67KG

♦ Standard accessory, it’s advantage is stable quality, durable material,and easy maintenance.

♦ Special design-control PP strap cooling time. It can make the PP strap to fasten well in any time.

♦ “Electricity-Saving” device, the motor automatically stops running at once after one circle strap to reduce the normal wear and to prolong the Strapping Machine life.

♦ Non-Fast heater plate, it will increase the work efficiency. The advanced P.C.B microchip circuit board control system,less malfunction and easy maintenance.

♦ Installing an auxiliary feed/reset switch and tension adjust switch at the control panel makes you operate more conveniently.Additional Information:

- Packaging Details: wooden b

SKU: n/a -

Carton Strapping Machines

Strapping Machine

Product Description

- Strapping Machine tension -40-400N adjustable

- Strapping Machine speed -0.53 sec./strap

- Strap width -6-15mm

- Power supply -220V/1P

- Power consumption -0.2KVA

- Strapping Machine size-809*520*760MM

- Strapping Machine weight -67KG

♦ Standard accessory, it’s advantage is stable quality, durable material,and easy maintenance.

♦ Special design-control PP strap cooling time. It can make the PP strap to fasten well in any time.

♦ “Electricity-Saving” device, the motor automatically stops running at once after one circle strap to reduce the normal wear and to prolong the Strapping Machine life.

♦ Non-Fast heater plate, it will increase the work efficiency. The advanced P.C.B microchip circuit board control system,less malfunction and easy maintenance.

♦ Installing an auxiliary feed/reset switch and tension adjust switch at the control panel makes you operate more conveniently.SKU: n/a

-

Weight Filling Machines

20-5000G SEMI WEIGHING FILLING MACHINE

Working voltage: 220V / 110V / 50HZ / 60HZ

Rated power: 350W

Packing speed: 6-15 bags / packing Weighing range: 20-5000G

Incorrect value: 2G (depending on the product to be filled)

This product is suitable for granular, powdered products, rice, millet, cereals, vegetable seeds, fertilizers, tea, wolfberry, dog food, fish food, dried fruits, nuts, medicinal salts, seasonings, red dates, walnuts, Chestnuts, dried longan, electronic originals, hardware originals, plastic parts, etc

SKU: n/a -

Weight Filling Machines

99.9 SEMI WEIGHING FILLING MACHINE

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 1 to 99.9 grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

The complete structure is made up of stainless steel with an open type bin. The structure is simple and easy to clean.

Digital numbers for denoting

- weight of the powder for a single output.

- The total standard expected weight per output.

- Number of times output received through the hopper

Requires electricity for its functioning. The supply requirement is a 220 volt 50 Hz AC power supply.

Please note that the weight of this full machine is 10 kg.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

SKU: n/a -

Weight Filling Machines

999 SEMI WEIGHING FILLING MACHINE

DESCRIPTION

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 100 to 999grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

Complete structure is made up of stainless steel with open type bin. Structure is simple and easy to clean.

Digital numbers for denoting

- weight of the powder for a single output.

- Total standard expected weight per output.

- Number of times output received through the hopper

Requires electricity for its functioning. Supply requirement is 220 volt 50 Hz AC power supply.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

SKU: n/a -

Semi-Auto Stretch Film Wrapping Machine

Semi-Auto Stretch Film Wrapping Machine

Product Description

As one of India’s leading manufacturers and suppliers, we are offering an exclusive range of Box Stretch Wrapping Machine. These machines are used for stretch film wrapping around the packaging boxes in different industries like cosmetic, textiles, electrical, automotive, food & beverage and fertilizer. We employ ultra modern techniques and quality approved materials to design these machines in accordance with industry set norms and standards. Our product is best known for its robust construction, corrosion resistant body and easy operation.Box Stretch Wrapping Machine Features:

1) Digital display to show stretch percentage and film consumption.

2) Continues motion mechanism that required very less maintenance.

3) Stringent quality checking done before final shipment.SKU: n/a -

Liquid Filling Machines

Double Head Paste Filling Machine

Filling Range

Machine Other Details

- This machine is the semi-automatic piston type pasty liquid filling

- This machine is reasonable in design, small and exquisite in model, saving the place.

- The part contacting materials is made of 316L & Hopper 304L stainless steel

- Both filling volume and filling speed can be adjusted, with high filling accuracy.

- Filling head adopts anti-leakage and lifting device.

- Hopper Capacity 40-50Kg.

Model Preferred Filling Range(ml)

- 100(ml) 5-100

- 500(ml) 20-500

- 1000(ml) 100-1000

- 2600(ml) 1000-2600

SKU: n/a -

Liquid Filling Machines

Single Head Paste Filling Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L & Hopper 304L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

Hopper Capacity 40-50Kg.SKU: n/a -

Liquid Filling Machines

Double Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.SKU: n/a -

Liquid Filling Machines

Liquid Single Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.SKU: n/a -

Sealer

FS-300 Plastic Sealing Machine

The Series plastic film sealer is the perfect sealer for PE and PP bags(including cellophane, bubble wraps, shrink wraps and thick heavy duty bags and so on), to package various kinds of candy, foodstuff, general merchandises, stationery, medicine, local specially, electric elements ect

SKU: n/a

-

L Sealer Machines

L-Bar Sealer

Sealing Cutting Machine can convey the products automatically into shrink tunnelthrough conveying belt for shrink packaging after sealing & cutting. Equipped with shrinktunnel to reach higher working capacity.

Sealing Cutting Machine is suitable for shrink packing electronic products, hardware,software, foodstuff, printing, pharmacy, floor, ceramics etc in small amount.Additional Information:

- Packaging Details: Wood

SKU: n/a -

Batch Coding

MY-380F Solid Ink Coding Machine

Backed by our efficient workforce, we are able to design and develop a wide range of Dry Ink Coding Machines. These are widely demanded by several industries like food, pharmaceutical and chemical. In addition to this, we have a team of expert quality controllers, which checks all the products on various parameters to ensure zero defect. We also provide tailor-made solution for all the products as per the specifications laid down by the customers.

Ideal for printing statutory markings/ coding on plastic / paper pouches, duplex boards / duplex cartons, labels etc.

Features:- Higher production speeds

- Batch feeding of print media

- Zero spillage of ink

- Lower coding costs

- Print counter

- Photo electric sensor for adjustment of print position

Additional Information:

- Delivery Time: 2 Days

SKU: n/a -

Can Sealer Sealing Machines

Manual Can Seamer

Can Seamer Intelligent can sealing machine Smart panel Beverage sealing machine milk tea coffee bubble drink bottle sealing

Product Name: Smart Can Sealing Machine

Type: Filling and Sealing Machine

Size: 550*350*202mm

Production capacity: 20 times / minute

Sealing width: 52mm

Sealing speed: 5 seconds

power:415w

Packaging material: plastic

Degree of automation: manual

Film thickness: 3mm

Weight: 35kg

Suitable for: Western food shop equipment, cake room equipment, Chinese food shop equipment, beverage shop equipment, coffee shop equipment, tea restaurant equipmentSKU: n/a -

Continuous Band Sealers

Packing Machine

Automatic Continuous Band Sealer and step less speed adjusting transmission mechanism. It can seal plastic films of various materials it is also suitable for small bags packaging .

Suitable for BOPP, Multi Layer, Laminated, Polysterpoly, Alu. Foil

All type of sealable materials in every thickness can be sealed .

Sealing length is unlimited.

Reliable Sealing quality.

Compact design.

Easy To Use.

Fast Work.Additional Information:

- Production Capacity: 50

- Delivery Time: 1 DAYS

- Packaging Details: CARTON

SKU: n/a -

Continuous Band Sealers

Continuous Band Sealer

Automatic Continuous Band Sealer and step less speed adjusting transmission mechanism. It can seal plastic films of various materials it is also suitable for small bags packaging .

Additional Information:

- Delivery Time: IMMEDIATE

- Packaging Details: CARTON PACKAGING

SKU: n/a -

Carton Strapping Machines

Automatic Strapping Machine

Features:Strap at quick speed and with high efficiency. Only takes 2 seconds for strapping one polypropylene strap.Instant heating systems, low voltage, light, safety,Automatic stopping devices save electricity and make it practical.Electromagnetic clutch, quick and smooth. Coupled-axle transmission, quick speed, low noise, low wear and tear, and low breakdown rate.Strap width from 8-19mm adjustable.

SKU: n/a -

Carton Strapping Machines

Automatic Strapping Machine

Rapid speed: 2.0sec/per cycle, 30cycles/per min

Easy Maintenance: No Greasing, Mechanism is stable and durable, Easy operation

Tension Adjustment: Can be adjustable at well, Max. Tension is over 90kgs

Precision Structure: Main machine’s component is made of aluminum alloy. Control System is compatible

Add on a safety device, built for 24 hrs continuous operation

Easy loading or unloading: To load or unload the strapping roll is convenient due to the dispenser is placed outside

Extensive applications: Can be independent operation or combine with other machines for unmanned

Electric appliance adopted: “MITSUBISHI” PLC control, and “ORMON” photoelectric switch control

Additional Information:

- Production Capacity: Built for 24 hrs continuous operation

SKU: n/a -

Carton Strapping Machines

Semi-Automatic Strapping Machine

- Strapping Machine tension -40-400N adjustable

- Strapping Machine speed -0.53 sec./strap

- Strap width -6-15mm

- Power supply -220V/1P

- Power consumption -0.2KVA

- Strapping Machine size-809*520*760MM

- Strapping Machine weight -67KG

♦ Standard accessory, it’s advantage is stable quality, durable material,and easy maintenance.

♦ Special design-control PP strap cooling time. It can make the PP strap to fasten well in any time.

♦ “Electricity-Saving” device, the motor automatically stops running at once after one circle strap to reduce the normal wear and to prolong the Strapping Machine life.

♦ Non-Fast heater plate, it will increase the work efficiency. The advanced P.C.B microchip circuit board control system,less malfunction and easy maintenance.

♦ Installing an auxiliary feed/reset switch and tension adjust switch at the control panel makes you operate more conveniently.Additional Information:

- Packaging Details: wooden b

SKU: n/a -

Carton Strapping Machines

Strapping Machine

Product Description

- Strapping Machine tension -40-400N adjustable

- Strapping Machine speed -0.53 sec./strap

- Strap width -6-15mm

- Power supply -220V/1P

- Power consumption -0.2KVA

- Strapping Machine size-809*520*760MM

- Strapping Machine weight -67KG

♦ Standard accessory, it’s advantage is stable quality, durable material,and easy maintenance.

♦ Special design-control PP strap cooling time. It can make the PP strap to fasten well in any time.

♦ “Electricity-Saving” device, the motor automatically stops running at once after one circle strap to reduce the normal wear and to prolong the Strapping Machine life.

♦ Non-Fast heater plate, it will increase the work efficiency. The advanced P.C.B microchip circuit board control system,less malfunction and easy maintenance.

♦ Installing an auxiliary feed/reset switch and tension adjust switch at the control panel makes you operate more conveniently.SKU: n/a

Trending products

Trending products20-5000G SEMI WEIGHING FILLING MACHINE

Working voltage: 220V / 110V / 50HZ / 60HZ

Rated power: 350W

Packing speed: 6-15 bags / packing Weighing range: 20-5000G

Incorrect value: 2G (depending on the product to be filled)

This product is suitable for granular, powdered products, rice, millet, cereals, vegetable seeds, fertilizers, tea, wolfberry, dog food, fish food, dried fruits, nuts, medicinal salts, seasonings, red dates, walnuts, Chestnuts, dried longan, electronic originals, hardware originals, plastic parts, etc

99.9 SEMI WEIGHING FILLING MACHINE

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 1 to 99.9 grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

The complete structure is made up of stainless steel with an open type bin. The structure is simple and easy to clean.

Digital numbers for denoting

Requires electricity for its functioning. The supply requirement is a 220 volt 50 Hz AC power supply.

Please note that the weight of this full machine is 10 kg.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

999 SEMI WEIGHING FILLING MACHINE

DESCRIPTION

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 100 to 999grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

Complete structure is made up of stainless steel with open type bin. Structure is simple and easy to clean.

Digital numbers for denoting

Requires electricity for its functioning. Supply requirement is 220 volt 50 Hz AC power supply.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

Semi-Auto Stretch Film Wrapping Machine

Product Description

As one of India’s leading manufacturers and suppliers, we are offering an exclusive range of Box Stretch Wrapping Machine. These machines are used for stretch film wrapping around the packaging boxes in different industries like cosmetic, textiles, electrical, automotive, food & beverage and fertilizer. We employ ultra modern techniques and quality approved materials to design these machines in accordance with industry set norms and standards. Our product is best known for its robust construction, corrosion resistant body and easy operation.

Box Stretch Wrapping Machine Features:

1) Digital display to show stretch percentage and film consumption.

2) Continues motion mechanism that required very less maintenance.

3) Stringent quality checking done before final shipment.

Double Head Paste Filling Machine

Filling Range

Machine Other Details

Model Preferred Filling Range(ml)

Single Head Paste Filling Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L & Hopper 304L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

Hopper Capacity 40-50Kg.

Double Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

Liquid Single Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

FS-300 Plastic Sealing Machine

The Series plastic film sealer is the perfect sealer for PE and PP bags(including cellophane, bubble wraps, shrink wraps and thick heavy duty bags and so on), to package various kinds of candy, foodstuff, general merchandises, stationery, medicine, local specially, electric elements ect

L-Bar Sealer

Sealing Cutting Machine can convey the products automatically into shrink tunnelthrough conveying belt for shrink packaging after sealing & cutting. Equipped with shrinktunnel to reach higher working capacity.

Sealing Cutting Machine is suitable for shrink packing electronic products, hardware,software, foodstuff, printing, pharmacy, floor, ceramics etc in small amount.

Additional Information:

MY-380F Solid Ink Coding Machine

Backed by our efficient workforce, we are able to design and develop a wide range of Dry Ink Coding Machines. These are widely demanded by several industries like food, pharmaceutical and chemical. In addition to this, we have a team of expert quality controllers, which checks all the products on various parameters to ensure zero defect. We also provide tailor-made solution for all the products as per the specifications laid down by the customers.

Ideal for printing statutory markings/ coding on plastic / paper pouches, duplex boards / duplex cartons, labels etc.

Features:

Additional Information:

Manual Can Seamer

Can Seamer Intelligent can sealing machine Smart panel Beverage sealing machine milk tea coffee bubble drink bottle sealing

Product Name: Smart Can Sealing Machine

Type: Filling and Sealing Machine

Size: 550*350*202mm

Production capacity: 20 times / minute

Sealing width: 52mm

Sealing speed: 5 seconds

power:415w

Packaging material: plastic

Degree of automation: manual

Film thickness: 3mm

Weight: 35kg

Suitable for: Western food shop equipment, cake room equipment, Chinese food shop equipment, beverage shop equipment, coffee shop equipment, tea restaurant equipment

Packing Machine

Automatic Continuous Band Sealer and step less speed adjusting transmission mechanism. It can seal plastic films of various materials it is also suitable for small bags packaging .

Suitable for BOPP, Multi Layer, Laminated, Polysterpoly, Alu. Foil

All type of sealable materials in every thickness can be sealed .

Sealing length is unlimited.

Reliable Sealing quality.

Compact design.

Easy To Use.

Fast Work.

Additional Information:

Continuous Band Sealer

Automatic Continuous Band Sealer and step less speed adjusting transmission mechanism. It can seal plastic films of various materials it is also suitable for small bags packaging .

Additional Information:

Automatic Strapping Machine

Features:Strap at quick speed and with high efficiency. Only takes 2 seconds for strapping one polypropylene strap.Instant heating systems, low voltage, light, safety,Automatic stopping devices save electricity and make it practical.Electromagnetic clutch, quick and smooth. Coupled-axle transmission, quick speed, low noise, low wear and tear, and low breakdown rate.Strap width from 8-19mm adjustable.

Automatic Strapping Machine

Rapid speed: 2.0sec/per cycle, 30cycles/per min

Easy Maintenance: No Greasing, Mechanism is stable and durable, Easy operation

Tension Adjustment: Can be adjustable at well, Max. Tension is over 90kgs

Precision Structure: Main machine’s component is made of aluminum alloy. Control System is compatible

Add on a safety device, built for 24 hrs continuous operation

Easy loading or unloading: To load or unload the strapping roll is convenient due to the dispenser is placed outside

Extensive applications: Can be independent operation or combine with other machines for unmanned

Electric appliance adopted: “MITSUBISHI” PLC control, and “ORMON” photoelectric switch control

Additional Information:

Semi-Automatic Strapping Machine

♦ Standard accessory, it’s advantage is stable quality, durable material,and easy maintenance.

♦ Special design-control PP strap cooling time. It can make the PP strap to fasten well in any time.

♦ “Electricity-Saving” device, the motor automatically stops running at once after one circle strap to reduce the normal wear and to prolong the Strapping Machine life.

♦ Non-Fast heater plate, it will increase the work efficiency. The advanced P.C.B microchip circuit board control system,less malfunction and easy maintenance.

♦ Installing an auxiliary feed/reset switch and tension adjust switch at the control panel makes you operate more conveniently.

Additional Information:

Strapping Machine

Product Description

♦ Standard accessory, it’s advantage is stable quality, durable material,and easy maintenance.

♦ Special design-control PP strap cooling time. It can make the PP strap to fasten well in any time.

♦ “Electricity-Saving” device, the motor automatically stops running at once after one circle strap to reduce the normal wear and to prolong the Strapping Machine life.

♦ Non-Fast heater plate, it will increase the work efficiency. The advanced P.C.B microchip circuit board control system,less malfunction and easy maintenance.

♦ Installing an auxiliary feed/reset switch and tension adjust switch at the control panel makes you operate more conveniently.

Laptops & Computers

20-5000G SEMI WEIGHING FILLING MACHINE

Working voltage: 220V / 110V / 50HZ / 60HZ

Rated power: 350W

Packing speed: 6-15 bags / packing Weighing range: 20-5000G

Incorrect value: 2G (depending on the product to be filled)

This product is suitable for granular, powdered products, rice, millet, cereals, vegetable seeds, fertilizers, tea, wolfberry, dog food, fish food, dried fruits, nuts, medicinal salts, seasonings, red dates, walnuts, Chestnuts, dried longan, electronic originals, hardware originals, plastic parts, etc

99.9 SEMI WEIGHING FILLING MACHINE

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 1 to 99.9 grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

The complete structure is made up of stainless steel with an open type bin. The structure is simple and easy to clean.

Digital numbers for denoting

Requires electricity for its functioning. The supply requirement is a 220 volt 50 Hz AC power supply.

Please note that the weight of this full machine is 10 kg.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

999 SEMI WEIGHING FILLING MACHINE

DESCRIPTION

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 100 to 999grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

Complete structure is made up of stainless steel with open type bin. Structure is simple and easy to clean.

Digital numbers for denoting

Requires electricity for its functioning. Supply requirement is 220 volt 50 Hz AC power supply.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

Semi-Auto Stretch Film Wrapping Machine

Product Description

As one of India’s leading manufacturers and suppliers, we are offering an exclusive range of Box Stretch Wrapping Machine. These machines are used for stretch film wrapping around the packaging boxes in different industries like cosmetic, textiles, electrical, automotive, food & beverage and fertilizer. We employ ultra modern techniques and quality approved materials to design these machines in accordance with industry set norms and standards. Our product is best known for its robust construction, corrosion resistant body and easy operation.

Box Stretch Wrapping Machine Features:

1) Digital display to show stretch percentage and film consumption.

2) Continues motion mechanism that required very less maintenance.

3) Stringent quality checking done before final shipment.

Double Head Paste Filling Machine

Filling Range

Machine Other Details

Model Preferred Filling Range(ml)

Single Head Paste Filling Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L & Hopper 304L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

Hopper Capacity 40-50Kg.

Double Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

Liquid Single Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

FS-300 Plastic Sealing Machine

The Series plastic film sealer is the perfect sealer for PE and PP bags(including cellophane, bubble wraps, shrink wraps and thick heavy duty bags and so on), to package various kinds of candy, foodstuff, general merchandises, stationery, medicine, local specially, electric elements ect

L-Bar Sealer

Sealing Cutting Machine can convey the products automatically into shrink tunnelthrough conveying belt for shrink packaging after sealing & cutting. Equipped with shrinktunnel to reach higher working capacity.

Sealing Cutting Machine is suitable for shrink packing electronic products, hardware,software, foodstuff, printing, pharmacy, floor, ceramics etc in small amount.

Additional Information:

MY-380F Solid Ink Coding Machine

Backed by our efficient workforce, we are able to design and develop a wide range of Dry Ink Coding Machines. These are widely demanded by several industries like food, pharmaceutical and chemical. In addition to this, we have a team of expert quality controllers, which checks all the products on various parameters to ensure zero defect. We also provide tailor-made solution for all the products as per the specifications laid down by the customers.

Ideal for printing statutory markings/ coding on plastic / paper pouches, duplex boards / duplex cartons, labels etc.

Features:

Additional Information:

Smartphones & Tablets

20-5000G SEMI WEIGHING FILLING MACHINE

Working voltage: 220V / 110V / 50HZ / 60HZ

Rated power: 350W

Packing speed: 6-15 bags / packing Weighing range: 20-5000G

Incorrect value: 2G (depending on the product to be filled)

This product is suitable for granular, powdered products, rice, millet, cereals, vegetable seeds, fertilizers, tea, wolfberry, dog food, fish food, dried fruits, nuts, medicinal salts, seasonings, red dates, walnuts, Chestnuts, dried longan, electronic originals, hardware originals, plastic parts, etc

99.9 SEMI WEIGHING FILLING MACHINE

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 1 to 99.9 grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

The complete structure is made up of stainless steel with an open type bin. The structure is simple and easy to clean.

Digital numbers for denoting

Requires electricity for its functioning. The supply requirement is a 220 volt 50 Hz AC power supply.

Please note that the weight of this full machine is 10 kg.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

999 SEMI WEIGHING FILLING MACHINE

DESCRIPTION

Semi weighing filling machine is used for accurate weighing and filling of ultrafine particles. Signals from the weight sensor are denoted on the Digital display that shows the weight of the particle output. It is used for the packaging of toners, additives, extinguishers etc. This weighing machine can carry 100 to 999grams of weight.

Semi Weighing Filling Machine working principle – It is the semi-automatic weighing and filling machine and the powder is poured into the carry bag held below the hopper. Its filling speed is 10 to 20 times per minute that means 600 bags per hour.

Technical specification

Complete structure is made up of stainless steel with open type bin. Structure is simple and easy to clean.

Digital numbers for denoting

Requires electricity for its functioning. Supply requirement is 220 volt 50 Hz AC power supply.

Workflow – At the very first stage, the powder is added to the filling container. The powder goes next to the weighing machine and the weight is displayed in the form of digital numbers over the screen. Hopper is fitted below where the carry bag is held to catch the powder.

Semi-Auto Stretch Film Wrapping Machine

Product Description

As one of India’s leading manufacturers and suppliers, we are offering an exclusive range of Box Stretch Wrapping Machine. These machines are used for stretch film wrapping around the packaging boxes in different industries like cosmetic, textiles, electrical, automotive, food & beverage and fertilizer. We employ ultra modern techniques and quality approved materials to design these machines in accordance with industry set norms and standards. Our product is best known for its robust construction, corrosion resistant body and easy operation.

Box Stretch Wrapping Machine Features:

1) Digital display to show stretch percentage and film consumption.

2) Continues motion mechanism that required very less maintenance.

3) Stringent quality checking done before final shipment.

Double Head Paste Filling Machine

Filling Range

Machine Other Details

Model Preferred Filling Range(ml)

Single Head Paste Filling Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L & Hopper 304L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

Hopper Capacity 40-50Kg.

Double Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

Liquid Single Head Packing Machine

This machine is the semi-automatic piston type pasty liquid filling

This machine is reasonable in design, small and exquisite in model, saving the place. The part contacting materials is made of 316L stainless steel

Both filling volume and filling speed can be adjusted, with high filling accuracy. Filling head adopts anti-leakage and lifting device.

FS-300 Plastic Sealing Machine

The Series plastic film sealer is the perfect sealer for PE and PP bags(including cellophane, bubble wraps, shrink wraps and thick heavy duty bags and so on), to package various kinds of candy, foodstuff, general merchandises, stationery, medicine, local specially, electric elements ect

L-Bar Sealer

Sealing Cutting Machine can convey the products automatically into shrink tunnelthrough conveying belt for shrink packaging after sealing & cutting. Equipped with shrinktunnel to reach higher working capacity.

Sealing Cutting Machine is suitable for shrink packing electronic products, hardware,software, foodstuff, printing, pharmacy, floor, ceramics etc in small amount.

Additional Information:

MY-380F Solid Ink Coding Machine

Backed by our efficient workforce, we are able to design and develop a wide range of Dry Ink Coding Machines. These are widely demanded by several industries like food, pharmaceutical and chemical. In addition to this, we have a team of expert quality controllers, which checks all the products on various parameters to ensure zero defect. We also provide tailor-made solution for all the products as per the specifications laid down by the customers.

Ideal for printing statutory markings/ coding on plastic / paper pouches, duplex boards / duplex cartons, labels etc.

Features:

Additional Information: